Introduction

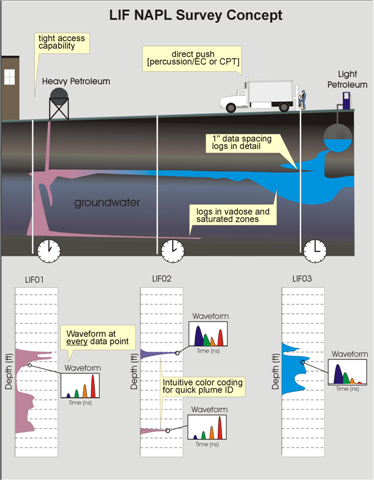

Laser-induced fluorescence (LIF) is a technique that uses laser light to excite fluorescent molecules that exist in the vast majority of hazardous non-aqueous phase liquids (NAPLs) such as petroleum fuels/oils, coal tars, and creosotes. Direct push logging of the NAPL’s inherent fluorescence with depth provides rapid and cost-effective delineation of NAPL. Conducting a multitude of LIF logs at NAPL sites allows a detailed NAPL conceptual site model (CSM).

The Science of LIF

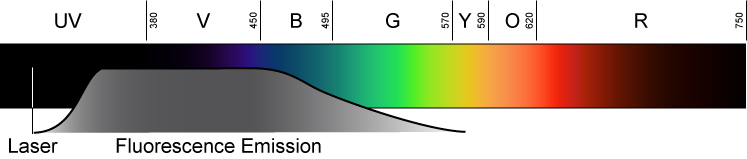

Laser light is narrow in wavelength and relatively powerful. As such, laser light is readily focused into fiber optics, allowing Dakota to deliver laser light remotely to samples and bring any light resulting from interaction with the laser light back to an instrument for analysis. Polycyclic aromatic hydrocarbons (PAHs) are highly fluorescent due to their molecular structure. Generally ultra-violet (UV) light is used to excite PAHs, which in turn produce violet to green fluorescence.

The fluorescence intensity and emitted colors of a single PAH is governed by the number of rings, arrangement of the rings, and degree of substitution. Petroleum NAPLs nearly always contain enough PAHs to be detected with LIF. This is illustrated in the image below showing layers of crude oil and diesel on wet sand, which demonstrate the utility of fluorescence for detecting petroleum. Notice that different colors of light are being emitted by the diesel vs. the oil. This is because the two NAPLs differ in their PAH distribution/content.

Finally, while photographs and the eye can’t capture the phenomenon, the PAHs in the crude oil and the diesel differ in the average time between the laser pulse and the emission of fluorescent light. Measuring this lifetime of fluorescence allows Dakota's LIF systems to log both the spectral and temporal nature of the emitted light to better differentiate between NAPLs and false positives.

LIF Site Investigation

Dakota's LIF screening tools take advantage of the same phenomenon shown in the previous diesel/crude example. Instead of the fuels/oils emitting light from within the clear glass jar, a transparent sapphire window is fitted into the side of a direct push probe that is pushed through the soil column. As this sapphire-windowed probe is advanced steadily down into the soil column at ~2cm/second, pulses of laser light are being sent down the rod string via fiber optics, where they exit the window and shine onto the face of the passing soil (without penetrating very far, if at all, into the formation). Any resulting fluorescence and/or scattered laser light that comes back into the window is brought up-hole by a second fiber, where the light is processed and analyzed in real time.

LIF systems typically log soils down to 50 feet below the surface (and >100 ft in ideal conditions) taking from 20-45 minutes start to finish with 300-350 feet of logging being typical for an 8 hour day. The LIF system displays and stores in real time exactly where NAPL fluorescence is occurring, including any differences in the fluorescence color and lifetime which change with differing NAPL types, weathering, or false positives. The goal is to quickly and non-subjectively survey the subsurface to generate an electronic data set used to develop a NAPL conceptual site model (CSM).

Key Elements

- LIF detects the PAH fluorescence in NAPL and this is how it logs NAPL vs depth

- LIF is compatible with both cone penetration test (CPT) and percussion based direct push drilling technologies

- LIF is a mature technology, with hundreds of miles of LIF logging at hundreds of sites in the last 20 years

- LIF is logged continuously with depth (2cm/second) - no data gaps or partial recovery

- Typical LIF production is 200-500 feet per day

- Experience has taught us there is almost never downward dragging of NAPL on the probe except when probing through the very softest of soils

- Waveforms, and the color-fill logs derived from waveforms, allow for the differentiation of NAPLs

- LIF detects NAPL equally well in both the vadose and saturated zones

- LIF detection limit ranges between 10 and 1000 mg/kg (TPH), depending on fuel type and soil matrix

- LIF does not respond to dissolved phase VOCs or SVOCs

- LIF does not detect BTEX (excitation wavelength for BTEX is incompatible with fiber optics)

- Soil matrix affects fluorescence – sands and gravels may have as much as 10 times higher response than clays and silts

- LIF's potential false positives include shell hash, meadow mat, peat, wood, and calcareous sands, but waveform shape and generally low intensity nearly always identify these as suspect

- LIF does not detect chlorinated solvent DNAPL because they aren’t fluorescent molecules – exception is chlorinated DNAPL that contains enough fluorophores (degreasing, industrial waste, etc.) - which is about 25% of DNAPLs tested recently

- UV LIF (UVOST) should NEVER be used to delineate coal tars and creosotes, use visible LIF instead (TarGOST) – some of these materials don’t fluoresce at all or have non-monotonic responses